- Community

- Industry Information

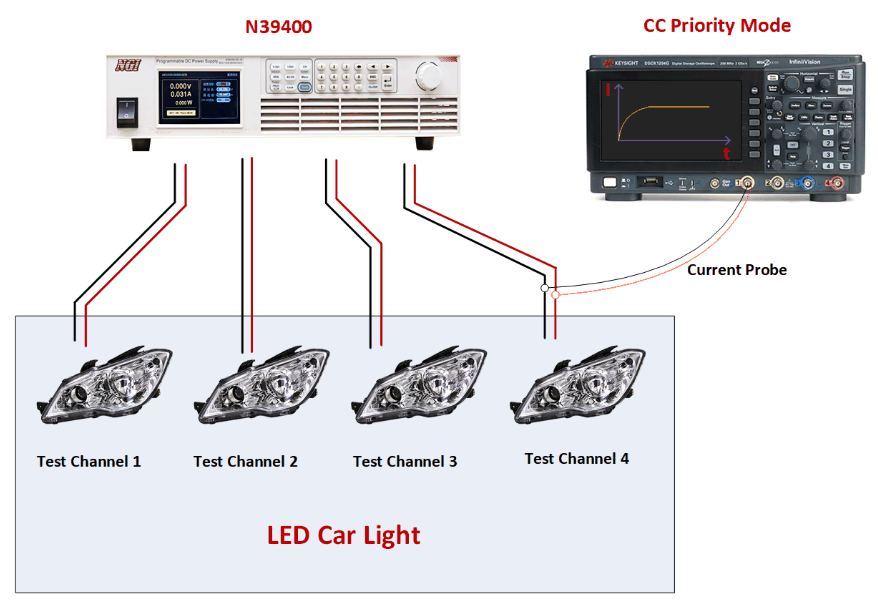

- Multi-channel DC Power Supply Application in LED Car Light Test

Multi-channel DC Power Supply Application in LED Car Light Test

December 22, 2020

December 22, 2020

Nowadays LEDs are used more and more widely as light sources in car lights. LED car lights have the features of high brightness, low power consumption and long life. With the gradual maturity of LED lighting industry, market competition is becoming increasingly fierce, while it puts higher and higher requirements on product quality. In this case, the high-accuracy multi-channel test power supply N39400 can effectively reduce the overall cost, allowing manufacturers to provide high-quality LED lighting products efficiently.

N39400 can be used to test the light distribution performance of LED car lights to inspect whether it meets the requirements of lighting and anti-glare. The input voltage required for the LED module of the headlamp is 13.2V during the test. Due to the sensitivity of LED light source, luminosity and color temperature, it must be aged before photometric measurement to make it work stable. At the same time, in terms of test voltage, it also has clear regulations on LED front fog lamps, headlamps and signal lamps.

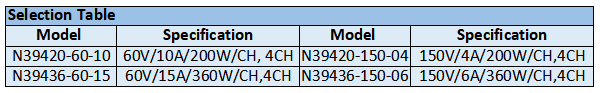

N39400 series is a high-accuracy&multi-channel programmable DC power supply with standard 19-inch 2U design, available for benchtop application and rack installation. N39400 standalone supports Max. 4 channels output, with channels isolated. Both local operation on front panel and remote control on a computer are supported. N39400 can be widely used in lab test, system integration test, production aging line, etc.

Main Features

- Automatic switch between CV and CC mode

- Single device with up to 4 channels, each channel isolated

- Low ripple and low noise

- Remote sense for accurate measurement

- Multiple protections: OVP, OCP, OTP and short circuit

- Intelligent fan control

- Lock function to avoid misoperation

- Dual LAN ports design

- CC&CV priority function

- Equipped with LCD screen and user-friendly interface

- Standard 19-inch 2U, available for rack installation

- LAN port and RS232 interface

CC&CV priority function

N39400 has the function of selecting priority of voltage-control loop or current-control loop, which enables N39400 to adopt the optimal test mode for different DUTs, and thus protect the DUT.

In CV priority mode, when the DUT requires reducing voltage overshoot during test, such as supplying power to a low-voltage processor or FPGA core, CV priority mode should be selected to obtain fast and smooth rise voltage.

In CC priority mode, when the DUT requires reducing current overshoot during test, or when the DUT is with low impedance, such as battery charging scenario, CC priority mode should be selected to obtain fast and smooth rise current.

export@ngitech.cn

export@ngitech.cn +86 19330858550

+86 19330858550 Feedback

Feedback