- Community

- Industry Information

- Application of Programmable DC Power Supply in Electric Bicycle Lithium Battery Charging Test

Application of Programmable DC Power Supply in Electric Bicycle Lithium Battery Charging Test

August 23, 2021

August 23, 2021

Electric bicycles, also known as e-bikes, are powered by batteries on the basis of bicycles. It combines the flexibility and lightness of bicycles with the advantages of electric vehicles that saves manpower and has high endurance, which can meet people's needs for short-distance travel. The demand for electric bicycles has increased substantially in recent years. Office workers in many cities use electric bicycles as a tool for commuting.

Most electric bicycles currently on the market are powered by lithium batteries. It is extremely important for lithium battery manufacturers to control and ensure the safe operation of lithium batteries through rigorous and reliable tests. As a very critical part of lithium battery testing process, the charge&discharge test directly affects the life and cycle performance of batteries. Lithium battery charge&discharge test requires the use of a DC power supply and a DC electronic load. The electronic load is used for discharge test. The DC power supply is used for charge test.

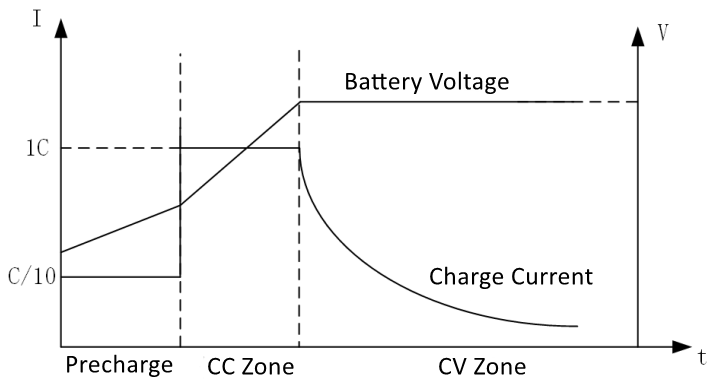

Charge test generally adopts constant current-constant voltage mode. Constant current-constant voltage charging avoids the tendency of overcharging in the later stage of CC charging, and also overcomes the problem of excessive charging current at the beginning of CV charging. In charge test, DC power supply needs to maintain a continuous energy output.

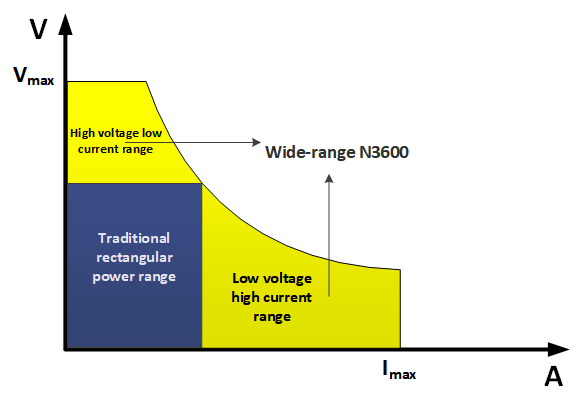

NGI N3600 series power supply is a high-voltage programmable DC power supply developed by NGI based on years of experience in battery testing and related applications. It adopts wide-range design with voltage up to 1000V. N3600 has various high-voltage or high-current models. It can be used to meet the charging test requirements of different specifications of lithium batteries.

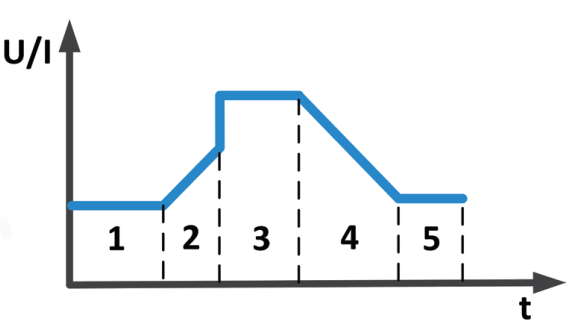

N3600 series wide-range power supply supports sequence (SEQ) edit function, allowing users to set output voltage, voltage slew, output current, current slew, and single step dwell time. SEQ function can make the power supply output automatically according to the sequence preset by the engineer. The parameters and dwell time of each step can be edited to produce various output changes. In the charge test of electric bicycle lithium battery, SEQ function can greatly improve the test efficiency and accuracy.

With the global popularity of electric bicycles, lithium batteries with superior cycle performance, high charging efficiency and no environmental pollution have become the mainstream choice for electric vehicle manufacturers. At the same time, the test requirements for lithium batteries are constantly increasing. As a measuring instrument manufacturer, NGI can provide test solutions for lithium batteries of electric bicycles to ensure the safe use of lithium batteries and contribute to urban green travel.

export@ngitech.cn

export@ngitech.cn +86 19330858550

+86 19330858550 Feedback

Feedback