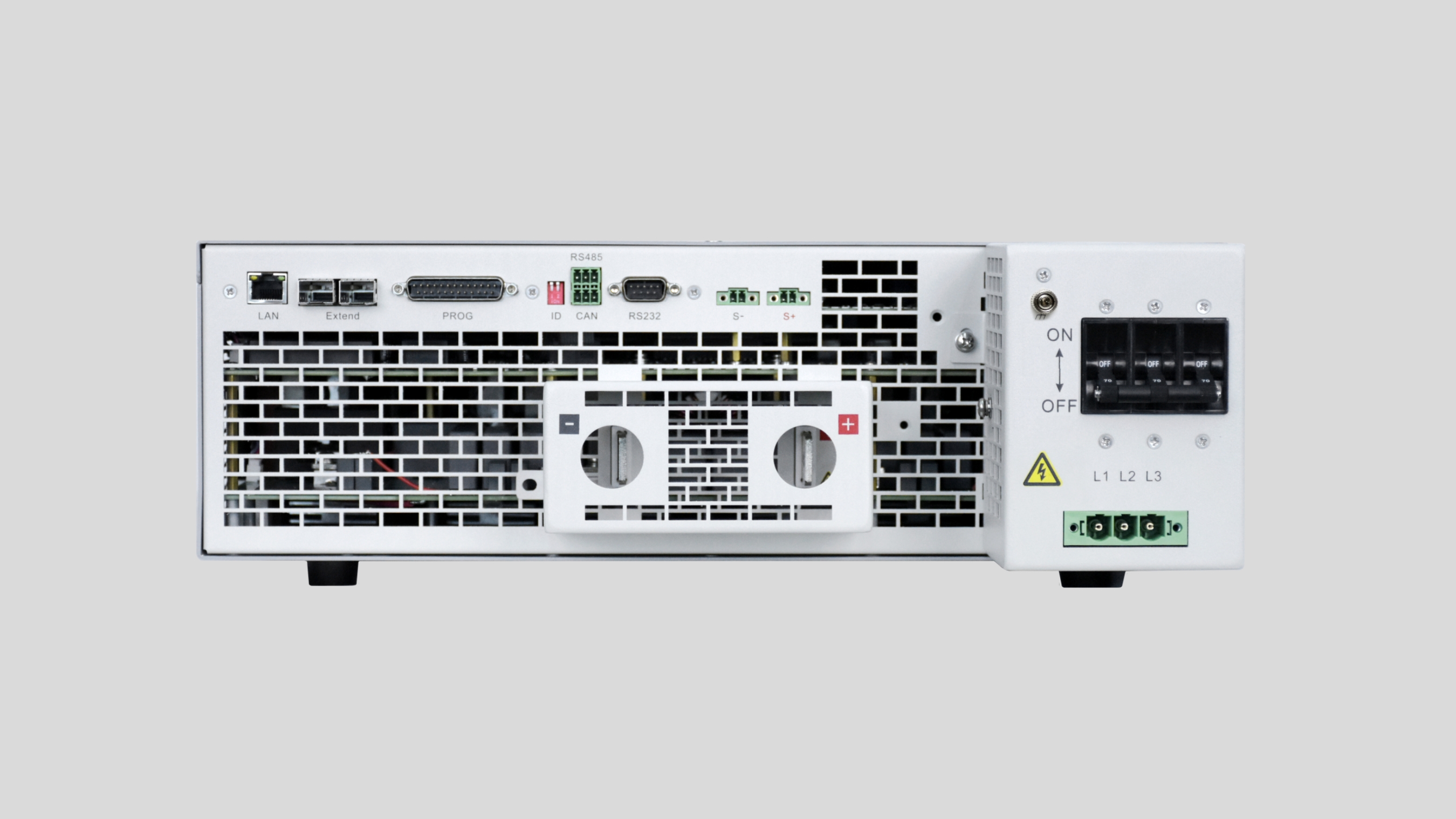

N35500 Series High Performance High Power Bidirectional Programmable DC Power Supply

The N35500 series is a high power bidirectional programmable DC power supply with dual quadrant, integrating bidirectional power supply and regenerative load to supply and absorb current. With the design of wide range and high power density, voltage range 0~1500V, output power up to 42kW in 3U chassis, it covers a wide range of DUT test applications. N35500 series are equipped with fast dynamic response, high accuracy output and measurement functions, and can also be configured with photovoltaic simulation, battery simulation and other software to help users realize accurate and efficient testing in multiple scenarios.●High power density, up to 42kW output in 3U chassis

●Wide output range, one can be used as multiple

●High-speed dynamic response, voltage rise and fall time ≤ 5ms

●Voltage accuracy: 0.02%+0.02%F.S.; Current accuracy: 0.1%+0.1%F.S.

●CC&CV Priority suitable for all types of test item

●Master/Master perallel up to MW level

●Source mode support CC/CV/CP/CR function

●Battery simulation, charge/discharge test, sequence test, waveform function etc.

●PV array I-V curve simulation function (optional)

●6.8 inch LCD screen for clear test information

●Standard with LAN/RS232/RS485/CAN communication

●Modbus-RTU, SCPI, CANopen protocol supportable

Seamless switch between source and load to regenerate energy

With the integration of power supply and regenerative load, N35500 series bidirectional power supply can be converted continuously seamlessly between the output and absorbed current, effectively avoiding voltage or current overshoot. Under load mode, N35500 series can not only provide external power, but also absorb power, and return electric energy to the grid cleanly, the regenerative efficiency up to 93%. It is widely used in lithium battery, UPS, BOBC and other equipment testing.

PV Cell Simulation (Optional)

With the characteristics of accurate measurement, high stability, fast response speed, N35500 series DC power supply with NS91000 can accurately simulate the I-V, P-V curve of the solar cell matrix. After setting Vmp, Pmp and other parameters, it can generate reports in compliance with regulations, which is used to test the static and dynamic maximum power tracking efficiency of PV inverters, and also can provide support for system simulation and core equipment testing of microgrids, distributed photovoltaic and other power systems.

Battery Simulation

N35500 series with NS81000 battery simulator software to meet the user's needs for different types of battery simulation, and improve the test efficiency. NS81000 has 7 standard battery model libraries, users only need to select the corresponding battery type, configure the basic capacity and protection parameters, the software can quickly generate the corresponding type of battery characteristic curve; And there are 2 types of custom battery characteristic curve, engineers can be based on the actual measurement of the battery curve data, import the data into the software and carry out simulation.

Wide range, high power density for saving cost and space

N35500 series DC power supply adopts systematic heat dissipation design, optimised device selection, main circuit topology, system heat dissipation, to achieve 42kW power output in 3U chassis, and adopts wide range output design, voltage up to 1500V, current up to 65A. With wide range and high power density design, N35500 series satisfy engineers' test application scenarios for products of various voltage/current levels, and greatly reducing purchase cost and space occupancy in laboratory or automated test systems.

CC&CVpriority function

N35500 series has the function of setting voltage-control priority or current-control loop priority, it can adopt the optimal working mode for testing according to the characteristics of DUT, so as to better protect DUT.

As shown in Figure 1, when it needs to reduce voltage overshoot during testing, such as powering a DC-DC power module, the voltage priority mode should be used to obtain a fast and smooth rising voltage.

As shown in Figure 2, when it needs to reduce current overshoot during testing or the component to be measured is low impedance such as in the battery charging scenario, the current priority mode should be used to obtain a fast and smooth rising current.

●Laboratory, production line ATE automatic test system

●Photovoltaic inverter, hydrogen fuel cell, solar cell matrix and other new energy fields

●Energy storage converter, UPS, photovoltaic storage machine and other energy storage fields

●BOBC, DC-DC, motor drive, charging pile and other automotive fields

●Charge/discharge test for power batteries, lead batteries, supercapacitors, etc.

●Test for aerospace electronics, high-power communications equipment, drones, etc.

export@ngitech.cn

export@ngitech.cn +86 19330858550

+86 19330858550 Feedback

Feedback