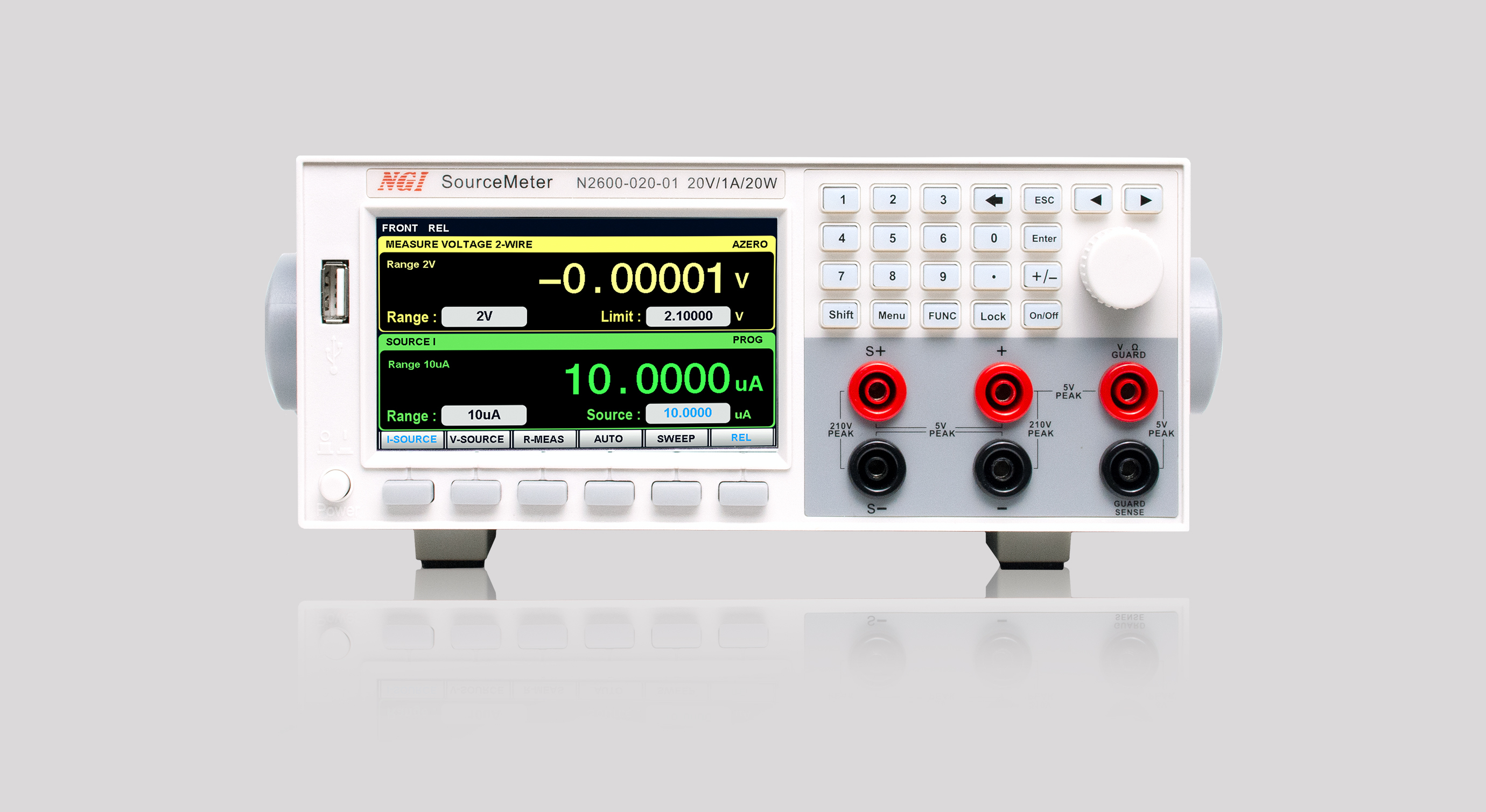

N2600 Series High Precision Source Meter (SMU)

■ SEQ test function and I-V characteristic analysis

■ Supporting signal generator and square wave

■ Digital I/O and external trigger control

■ LAN port, RS232 interface

■ Supporting SCPI protocol

■ Front USB port, supporting screenshot storage

Remark【1】:Only N2610-100-03 supports this function.

N2600 series adopts a standard ½ 19-inch 2U chassis. Integrating source and measure circuits into a compact standalone instrument greatly reduces test system development, setup and maintenance time, while saving test bench space and reducing the overall purchase cost.

The precision coupling feature of N2600 Series SMU offers many advantages over discrete instruments. While providing accurate output voltage and current sources, it can measure current, voltage and resistance, and has a high test response speed, which can protect the DUT from being damaged under occasional overload, thermal runaway, etc.

Four-quadrant operation as source or load

Four quadrants: The power quadrant refers to the quadrant diagram formed with voltage as X-axis and current as Y-axis. In the first and third quadrants, voltage and current go same direction, and SMU supplies power to DUT, which is called the source mode. In the second and fourth quadrants, voltage and current go reverse direction, DUT discharges to SMU, and SMU passively absorbs the incoming current and provides a return path for the current, which is called the sink mode.

I-V characteristics

Usually, I-V characterization of a DUT requires the use of highly sensitive ammeter, voltmeter, voltage source, and current source. The process of programming, synchronizing, connecting, measuring, and analyzing each of these instruments is complex, time-consuming, and takes up excessive test bench space.N2600 series can greatly simplify the test process and reduce test bench space occupation. N2600 provides 4-quadrant operation. When operating in 1st and 3rd quadrant, N2600 acts as a power source to output power to the DUT. When operating in 2nd and 4th quadrant, N2600 acts as a sink (load) to absorb energy. In source or sink mode, N2600 can measure voltage, current, and resistance, making it an ideal selection for I-V characterization of DUT, such as material research, electronics, semiconductor, etc.

Power envelope

Different from traditional matrix power supply, under the same power, on N2600, users can choose high voltage and low current or low voltage and high current output according to actual needs. The source/sink limit of N2600 are also different by choosing different specifications.

N2600-020-01 source/sink limit: ±21V@±1.05A N2600-200-01 source/sink limit: ±21V@±1.05A ±210V@±105mA

Various sweep modes

N2600 supports linear staircase sweep, logarithmic staircase sweep, custom sweep and built-in sweep. The sweep mode runs automatically after setting the functional relation and protection point, which greatly speeds up the test efficiency. The sweep can be set up to single-event or continuous operation, making N2600 ideal for I/V, I/R, V/I, and V/R characterization.

- Linear staircase sweep: sweep from start level to end level in equal linear steps

- Built-in sweep: 100 settings are stored in the system for call.

2/4/6-wire resistance measurement

N2600 SMU integrates a high-precision digital multimeter function, which not only supports high-precision voltage and current measurement, but also supports 2/4/6-wire resistance measurement, which is suitable for various test scenarios.

2-wire resistance measurement is suitable for test scenarios where the resistance of the test leads is much smaller than the resistance to be measured, regardless of the voltage drop loss caused by the test leads.

4-wire resistance measurement is suitable for measuring low-value resistances. N2600 SMU has an auto-correction function that eliminates test lead effects.

6-wire resistance measurement: When the measured resistance is connected in parallel with other resistances, the other resistances will shunt and affect the test. N2600 SMU uses 6-wire resistance measurement to enable in-situ measurement of resistors on the PCB.

Automation to improve production test efficiency

N2600 SMU provides high-precision voltage and current sources while making high-precision measurements, without changing connections or using additional devices, which greatly improves production test efficiency. At the same time to meet the throughput requirements of production applications, N2600 has many built-in functions to run complex test sequences without using the slow computer control or GPIB communication.

Big LCD screen

N2600 SMU is equipped with a 4.3-inch LCD screen. Compared with traditional VFD screens, LCD screens have the advantages of low power consumption, small size and low radiation. At the same time, combined with professional interface design, N2600 is easy to use, and the readback display is intuitive and comprehensive.

Remote control for easy system integration

NGI provides users with a free PC application software, which can meet the testing needs of various application scenarios.N2600 SMU is equipped with LAN port and RS232 interface, and supports SCPI/Modbus commands.

export@ngitech.cn

export@ngitech.cn +86 19330858550

+86 19330858550 Feedback

Feedback